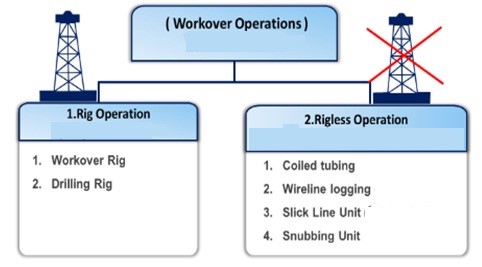

Workover of the well after being linked to production as a result of any problem occurring in the well during the production period With rig (workover rig ) or without (rigless)

According to the condition of the well

Workover operation are very important to maintain the production of the wel

Application of Workover operation :

- Repairing or replacing some of the equipment inside the well that was damaged

- repairing well head and surface installations

- sand production control

- Artificial lift equipment installation and maintenance

- formation stimulation

- isolation of non wanted producing

- remedial cementing

- fishing operation

- well re-completion

- Converting the production well into an injection well

- well suspension and temporarily abandonment

- well abandonment

Types of Workover Operation:

With rig-operations:

- bridge plug or cement plug

- Milling Packer or Bridge Plug

- Perforation with tcp

- install tubing or downhole equipment.

- Install equipment artificial lift like ESP or gas lift

- (Install equipment sand control.

- (well re-completion

- side trak

- Deeping the well

- abandon the well

rig –less operation

- Coiled tubing

- Wireline logging

- Slick line unit

- Snubbing unit

Coiled tubing operation

- Drilling

- Logging

- Perforation

- Stimulation ,acidizing , fracturing

- Nitrogen lifting

- Fishing

- Remedial cementing

- Setting and retrieving bridge plugs

- Removal sand from wellbore

- Wellbore cleanout (asphalt )